How to ring an electric motor with a multimeter

The electric motor is the main component of any modern household electrical equipment, whether it be a refrigerator, vacuum cleaner or other unit used in the household. If any device fails, first of all, it is necessary to establish the cause of the breakdown. To find out if the motor is in good condition, it must be checked. It is not necessary to carry the device to the workshop for this, it is enough to have an ordinary tester. After reading this article, you will learn how to check an electric motor with a multimeter, and you can cope with this task yourself.

Content

Which motors can be checked with a multimeter?

There are various modifications of electric motors, and the list of their possible malfunctions is quite large. Most problems can be diagnosed using a regular multimeter, even if you are not an expert in this area.

Modern electric motors are divided into several types, which are listed below:

- Asynchronous, three-phase, squirrel-cage rotor. This type of electrical powertrain is the most popular due to its simple device that allows easy diagnosis.

- Asynchronous capacitor, with one or two phases and squirrel-cage rotor. Such a power plant is usually equipped with household appliances powered by a conventional 220V network, which is most common in modern homes.

- Asynchronous, equipped with a phase rotor. This equipment has a more powerful starting torque than squirrel-cage motors, and therefore it is used as a drive in large power devices (hoists, cranes, power plants).

- Collector, direct current. These motors are widely used in automobiles, where they act as a drive for fans and pumps, as well as for power windows and wipers.

- Collector, alternating current. Hand-held power tools are equipped with these motors.

The first step in any diagnosis is visual inspection. Even if burnt windings or broken off parts of the motor are visible with the naked eye, it is clear that further inspection is pointless, and the unit must be taken to the workshop. But often the inspection is not enough to identify problems, and then a more thorough check is necessary.

Repair of asynchronous motors

The most common asynchronous power units for two and three phases. The procedure for diagnosing them is not entirely the same, so you should dwell on this in more detail.

Three phase motor

There are two types of malfunctions of electrical units, regardless of their complexity: the presence of contact in the wrong place or its absence.

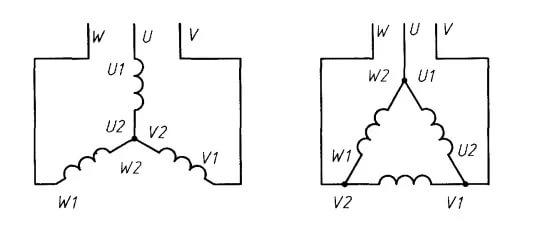

A three-phase AC motor has three coils that can be connected in a delta or star shape. There are three factors that determine the performance of this power plant:

- Correctness of winding.

- Insulation quality.

- Reliability of contacts.

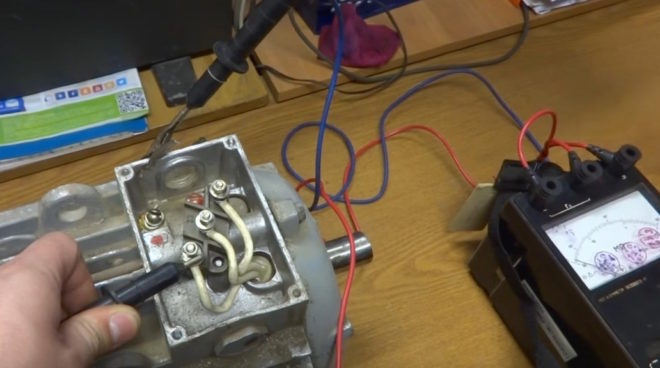

A short circuit to the case is usually checked using a megohmmeter, but if it is not there, you can get by with an ordinary tester by setting the maximum resistance value on it - megaohms. There is no need to talk about high measurement accuracy in this case, but it is possible to get approximate data.

Before measuring resistance, make sure the motor is not connected to the mains, otherwise the multimeter will become unusable.Then you need to calibrate by setting the arrow to zero (the probes must be closed in this case). It is necessary to check the serviceability of the tester and the correctness of the settings by briefly touching one probe to the other, each time before measuring the resistance value.

Place one test lead on the motor housing and make sure there is a contact. After that, take the readings of the device, touching the engine with the second probe. If the data is within normal limits, connect the second probe to the output of each phase in turn. A high resistance index (500-1000 and more megohms) indicates good insulation.

How to check the insulation of the windings is shown in this video:

Then you need to make sure that all three windings are intact. You can check this by ringing the ends that go into the motor terminal box. If any winding breakage is detected, the diagnostics should be stopped until the malfunction is eliminated.

The next check point is the definition of short-circuited turns. Quite often, this can be seen during visual inspection, but if the windings look normal externally, then the fact of a short circuit can be established by the unequal consumption of electric current.

Two Phase Electric Motorb

Diagnostics of power units of this type is slightly different from the above procedure. When checking a motor equipped with two coils and powered by a conventional electrical network, its windings must be ringed with an ohmmeter. The resistance indicator of the working winding should be 50% less than that of the starting winding.

The resistance to the case must be measured - normally it should be very large, as in the previous case. A low resistance indicator indicates the need to rewind the stator. Of course, to obtain accurate data, such measurements are best done with a megohmmeter, but this is rarely possible at home.

Checking collector motors

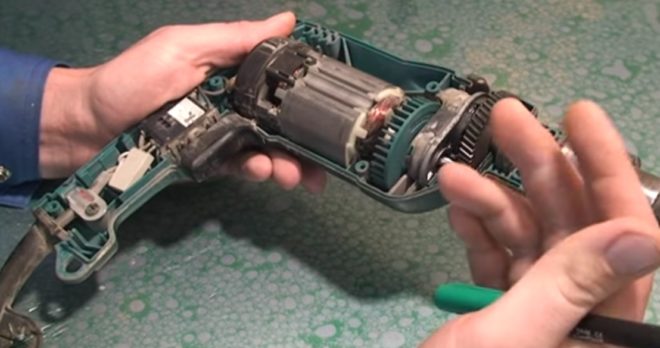

Having dealt with the diagnostics of asynchronous motors, let's move on to the question of how to ring an electric motor with a multimeter, if the power unit is of the collector type, and what are the features of such checks.

To properly check the performance of these motors using a multimeter, you need to proceed in the following order:

- Switch on the ohm tester and measure the resistance of the collector lamellas in pairs. Normally, these data should not differ.

- Measure the resistance indicator by applying one probe of the device to the armature body and the other to the collector. This indicator should be very high and tend to infinity.

- Check the stator for winding integrity.

- Measure the resistance by applying one probe to the stator housing and the other to the terminals. The higher the number obtained, the better.

Checking the electric motor with a multimeter for an interturn short circuit will not work. For this, a special apparatus is used with which the anchor is checked.

A detailed check of the motors of a power tool is shown in this video:

Features of checking electric motors with additional elements

Electric power plants are often equipped with additional components designed to protect equipment or optimize its performance. The most common parts built into a motor are:

- Thermal fuses. They are set to operate at a specific temperature in order to avoid combustion and destruction of the insulating material. The fuse is removed under the insulation of the windings or fixed to the body of the electric motor with a steel bow. In the first case, access to the conclusions is not difficult, and they can be checked without problems using a tester. You can also use a multimeter or a simple indicator screwdriver to determine to which detachable legs the protective circuit goes.If the thermal fuse is in good condition, then it should show a short circuit during measurement.

- Thermal fuses can be successfully replaced by temperature switches, which are either normally open or closed (the second type is more common). The element mark is affixed to its body. The relay for various types of motors is selected in accordance with the technical parameters, which can be found by reading the operating documents or finding the necessary information on the Internet.

- Three-pin engine speed sensors. Usually they are equipped with motors of washing machines. The basis of the principle of operation of these elements is the change in the potential difference in the plate through which a weak current passes. Power is supplied through the two end terminals, which have a small resistance and should show a short circuit when tested. The third pin is checked only in operating mode, when a magnetic field acts on it. Do not measure the power supply to the sensor with the engine running. It is best to remove the power unit altogether and apply current separately to the sensor. Rotate the axis to generate pulses at the sensor output. If the rotor is not equipped with a permanent magnet, you will have to install it during the test, having removed the sensor first.

A regular multimeter is usually sufficient to diagnose most problems that can occur in electric motors. If it is not possible to establish the cause of the malfunction with this device, the check is carried out using high-precision and expensive devices that are available only to specialists.

This material contains all the necessary information on how to properly check an electric motor with a multimeter in a domestic environment. When any electrical equipment fails, the most important thing is to ring the motor winding in order to exclude its malfunction, since the power plant has the highest cost in comparison with other elements.