Choosing an electrical wire for outdoor wiring on the street

When organizing wiring indoors, many do not think about choosing a wire and often use the first option that comes across. When laying outdoors, this approach is unacceptable, because there are a number of negative factors here - temperature fluctuations, the influence of UV rays, high humidity, the risk of mechanical stress, and others. This is why it is important to know which wire to use for outdoor wiring and what to consider when installing it.

Content

Design and marking features

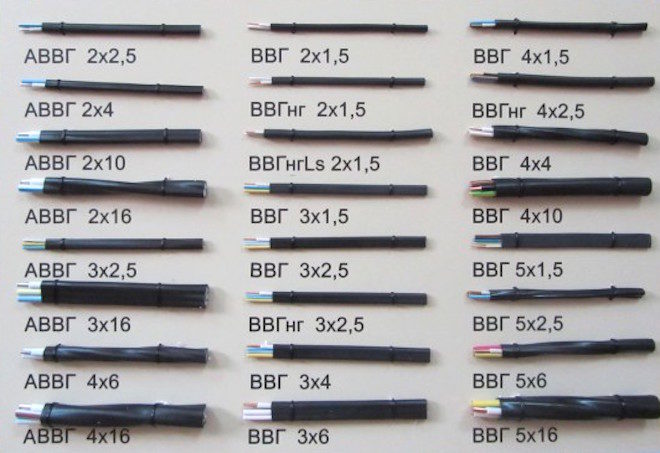

In order not to be mistaken with the choice, it is important to understand the intricacies of marking and decoding of each letter in the name of the product. All cables are conventionally divided into two categories - single-core and multi-core.

The vein itself can be solid or formed from many wires of a small cross section. In the second case, the wire acquires additional softness, bends better and practically does not break in case of bending.

In the manufacture of cores, as a rule, two types of metal are used - aluminum and copper. The exception is special products where the use of alloys is allowed. By the way, the cable for street wiring SIP has aluminum-steel conductors.

For laying at home, wires with copper conductors are used, which have better characteristics and are designed for high currents. Aluminum conductors were previously used due to their low cost and greater availability, but today they are abandoned due to their poor resistance to corrosion and brittleness.

In the manufacture of insulation for wires, the following can be used:

- Rubber.

- PVC material.

- Polyethylene.

- Lead and other materials.

Wire marking

If the conductor material is aluminum, the wire is marked with the letter A. Copper is the default conductor material and is therefore not reflected in the marking.

According to the purpose, the wires are marked as follows: W - installation, K - control, M - installation and others.

Insulation (material):

- P - polyethylene.

- H - non-flammable rubber.

- B - PVC.

- K - nylon.

- Ps - self-extinguishing polyethylene.

- C - lead.

- PV - vulcanizing polyethylene and others.

Cable protection level:

- B - with an armored shell.

- G - without armor (flexible).

- A - asphalted and so on.

In addition to the letter designation, there is also a digital marking. In it, the first symbol reflects the number of cores, the second - the cross-section, and the third - the rated voltage class. If there is no first digit, the cable has one core.

Which wire to use for outdoor wiring: the best options

We smoothly approached the main question, which wire to use for outdoor wiring, in order to be sure of its reliability and ability to withstand negative natural influences. The main requirements for such products are combustion resistance, strength and non-hygroscopicity.

The most popular types are:

SIP - power cable for the street, capable of conducting voltages up to 1000 V. Structurally, the product is a group of wires with individual insulation and aluminum conductors. Such products have their own subtypes (SIP -1, 2, 3 and so on) and are produced in many countries of the world. The main feature is the black wire insulation. The use of such a cable guarantees greater reliability during air laying and reduces installation costs. An additional advantage is its compactness, which makes it possible to use the cable even in conditions of limited space.

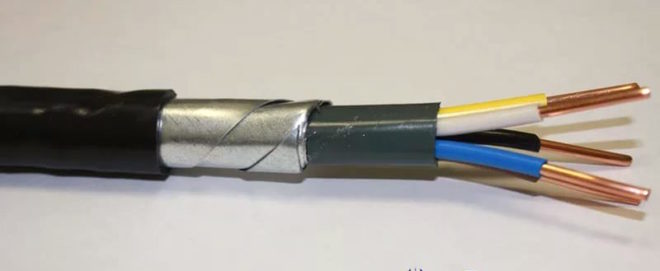

AVBbShv is a product based on a group of wires with aluminum conductors combined under one armored sheath. One of the types of cable is VBbShv - an option with copper wires. Feature - the possibility of laying in the ground without the use of additional protection and resistance to mechanical stress. Main characteristics:

- The presence of steel tape in the shell.

- Wire insulation is made in different colors for easy dialing and connection.

- The outer shell is black.

- Resistant to moisture and temperature extremes.

- Service life - 30 years.

Due to the presence of armor, cable products of this type are characterized by increased rigidity, which creates additional problems during the installation process.

NYY is a cable that is versatile and reliable in operation. May have copper or aluminum conductors. This product is increasingly used for external wiring in the ground or in the air, as well as for connecting electrical receivers indoors. Main characteristics:

- Resistant to water and fire.

- Compliance with international standards.

- The presence of multi-colored wire insulation.

- Convenience of organizing wiring on the street.

- Black outer sheath of PVC plastic.

- Resistance to temperature extremes.

- Service life - 30 years.

This cable is available in many factories due to its versatility and reliability. The main competitor of the product is the VBbshv cable, which was mentioned above.

NYM - reliable cable, which are actively used in production and when creating wiring on the street. Its peculiarity lies in its versatility and the possibility of operation in various conditions. Specifications:

- Conformity to the norms of the German Electrical Engineering Association.

- Heat resistance and ability to work in a wide temperature range.

- Non hygroscopicity and strength, which allows you to lay the product in concrete or in a layer of plaster.

- The cross section is round, the color is gray.

- Resistant to fire.

Sun protection is recommended for outdoor wiring using NYM. Such cable products are manufactured in many factories located in Europe and Russia. Some manufacturers make cables according to individual specifications, but such products have a lower price and, accordingly, worse quality. The use of such cables for organizing external wiring is not recommended.

Alternative solutions

In addition to those discussed above, it is worth highlighting a number of other brands of cables used in organizing street wiring:

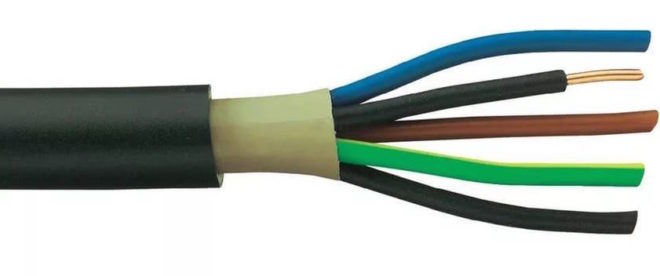

- PVS - flexible cable with PVC sheath and marked wires. The number of lived from two to five.

- VVG - power cable with a number of cores from one to five... It features a flat shape and double insulation, which allows the use of the wire outdoors.

- PV, APV, PV1 and other wires are suitable for laying external wiring, but only if they are in pipes. The main disadvantage is the presence of single insulation, which makes them unprotected to mechanical stress.

- VBbvng is a product characterized by fire resistance and flexibility. The number of lived from one to six. Most often used to connect portable devices.

Since the tragedy that struck New York in 2000 at the Bell Telecom building, cable manufacturers have changed safety standards. The reason is the release of toxic gases by the braid of the wires during the combustion process, because of which most of the people died. In addition, toxic gases negatively affect sophisticated electronics. That is why, at the present stage, manufacturers are focusing on the manufacture of non-combustible wires, characterized by a low level of gas and smoke emission.

Rules for installing wiring on the street

When choosing wires for outdoor wiring it is important to take into account the features of its laying. There are a number of rules regarding protection and distance to residential buildings.So, the distance from the cable to the porch should be at least 250 cm, and to the balcony or window - 100 and 50 cm, respectively. If the wiring is vertical, the distance from the ground should be 275 cm, to the balcony or window opening - 100 and 75 cm, respectively.

If the wire is laid along the wall, a number of rules should be followed:

- In the case of using individual wires, the use of plastic or metal pipes is mandatory.

- The connection of the wires must be provided using terminal blocks (twisting is prohibited).

- When suspending a cable between buildings, it is imperative to use a cable and a corrugated sleeve.

- Wiring should only be made in sealed junction boxes.

- Roof wiring is prohibited.

In the process of laying wires on the street, it is worth considering a number of important nuances. So, the network of a private house can be connected to a power source of 3 or single-phase voltage (380 or 220 volts, respectively). If the wiring is done by air, it is recommended to use the SIP-4 wire.

Armored wires of the VBShv or AVBShv brands are more suitable for underground laying. A feature of such products is resistance to water and mechanical damage. For outdoor wiring, as a rule, wires with an aluminum core of a larger cross-section are used, which reduces installation costs.

Brief recommendations for the laying method

Another factor that must be taken into account is the installation method. Most popular options:

- Air. This option is suitable for cases when the cable has a length of 3 meters. The advantages of the method are high installation speed and ease of maintenance. On the other hand, aesthetics suffers and the resource of the product decreases. In the process of such a laying, a steel cable is used, to which the cable itself is attached with the help of ties.

- Underground. This method is used in most cases when you need to lay a long cable. Installation is carried out in several stages - choosing the type of cable, marking the location and laying. The depth of the trench is about 70 cm. There should be a “pillow” of sand about 8-10 centimeters thick below. The cable should be laid without tension, after which it is covered with sand, soil and finally rammed.

An example of laying a cable in a trench is shown in this video:

Outcome

When choosing a wire for outdoor installation, it is worth considering many factors, as well as thinking in advance about the method of laying. Remember that your peace of mind, safety, and sometimes life depends on the correct choice of cable and compliance with the rules of the PUE during the installation process.