How to connect aluminum to copper wire

In residential buildings that were built in Soviet times, electrical wiring was carried out with aluminum wires. Professional electricians prefer to make modern household network with copper wires. Therefore, whether we like it or not, but often we have to face the problem of how to connect copper and aluminum wires. Do not listen to those who will tell you that this should not be done categorically. Of course, not all methods are suitable for this case, however, connecting electrical aluminum and copper wires is a completely solvable task. The main thing is to do everything right.

These two metals have different chemical properties, which affects the quality of their connection. But there were clever heads who figured out how to connect two conductors, while excluding direct contact between them.

We will consider all the existing options for how you can connect copper and aluminum wire, but first, let's figure out why this cannot be done with an ordinary twist and what is the reason for such incompatibility?

Content

Reasons for incompatibility

The main reasons for the undesirable connection between these two metals are covered in an aluminum wire.

There are three reasons, but they all lead to the same result - over time, the contact connection of the wires weakens, begins to overheat, the insulation melts and a short circuit occurs.

- Aluminum wire has the ability to oxidize when exposed to moisture in the air. This happens much faster on contact with copper. The oxide layer has a higher resistivity than the aluminum metal itself, which leads to excessive heating of the conductor.

- Compared to a copper conductor, aluminum is softer and has less electrical conductivity, due to which it heats up more. During operation, conductors are heated and cooled many times, resulting in several cycles of expansion and contraction. But aluminum and copper have a big difference in the amount of linear expansion, so a change in temperature leads to a weakening of the contact connection, and a weak contact is always the cause of strong heating.

- The third reason is that copper and aluminum are galvanically incompatible. If you twist them, then when an electric current passes through such a node, even with minimal humidity, a chemical electrolysis reaction will occur. It, in turn, causes corrosion, as a result of which, again, the contact connection is broken, and as a result, heating, melting of insulation, short circuit, and fire.

Bolted connection

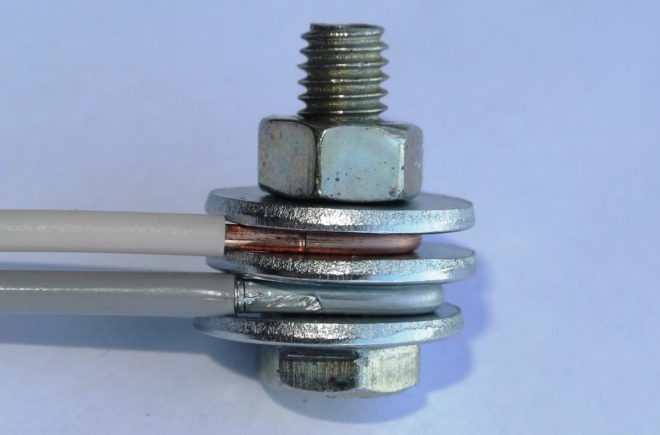

Bolted connection of aluminum wires with copper wires is considered the most affordable, simple, fast and reliable. You will need a bolt, a nut, some steel washers, and a wrench to work.

Of course, it is unlikely that you will be able to apply this method to connect wires in an apartment junction box, because now they are produced in miniature sizes, and the resulting electrical unit will be very cumbersome. But if you still have Soviet-era boxes in your house or when you need to make a connection in a switchboard, then this bolted method is best suited.In general, it is considered an ideal option when it is necessary to switch absolutely incompatible conductors - with different sections, made of different materials, multicore with single conductors.

It is important to know that using the bolt method, you can connect more than two conductors (their number depends on how long the bolt is).

You will need to do the following:

- Strip each wire or cable to be connected from the insulating layer by 2-2.5 cm.

- From the stripped ends, form rings around the diameter of the bolt so that they can easily be put on it.

- Now take a bolt, put a washer on it, then a ring of a copper conductor, again a washer, a ring of an aluminum conductor, a washer and tighten everything securely with a nut.

- Insulate the connection with insulating tape.

Most importantly, do not forget to place an intermediate washer between the aluminum and copper wires. If you will connect several different conductors, then you do not need to put an intermediate washer between the conductors of the same metal.

Another advantage of this connection is that it is detachable. At any time, you can unwind it and, if necessary, connect additional wires.

How to properly bolt the wires is shown in detail in this video:

Clamp "Nut"

Another good way to connect copper and aluminum wires is to use nut clamps. It is more correct to call this device a branch compression. This is already electricians nicknamed him "nut" because of the external resemblance.

It is a dielectric polycarbonate body with a metal core (or core) inside. The core is two dies, each of which has a groove for a certain conductor cross-section, and an intermediate plate, all of which are bolted together.

Such clamps are sold in any electrical store, they are of different types, which depend on the cross-section of the wires to be connected. The disadvantage of such a device is its non-tightness, that is, there is a possibility of moisture, dust and even fine litter. For the reliability and quality of the connection, it is better to wrap the nut with insulating tape on top.

The process of connecting wires using such a clamp is as follows:

- Disassemble the compression body by prying and removing the retaining rings with a thin screwdriver.

- On the wires to be connected, strip the insulating layer to the length of the dies.

- Unscrew the retaining bolts and insert the bare conductors into the flat grooves.

- Tighten the bolts, position the plate in the compression housing.

- Close the housing and put on the retaining rings.

A practical example of using the nut clamp is shown in this video:

Terminal block

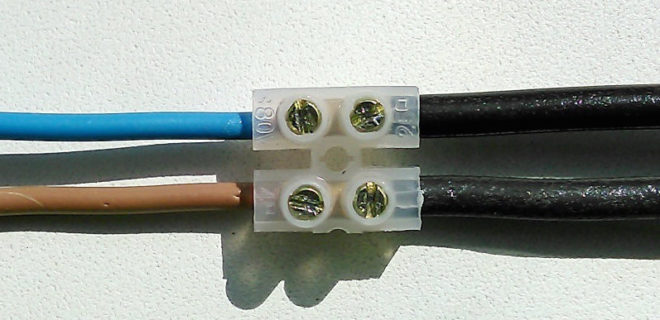

A cheap and simple solution to the question of how to connect aluminum wires with copper ones is to use terminal blocks. To buy them now is not a problem at all, moreover, you can buy not a whole section, but ask the seller to cut off the required number of cells. Terminal blocks are sold in different sizes, depending on the size of the conductors they connect.

What is such a block? This is a polyethylene transparent frame designed for several cells at once. Each cell has a tubular brass sleeve inside. From opposite sides, the ends of the wires to be connected must be inserted into this sleeve and tightened with two screws.

The use of terminal blocks is very convenient in that you can always cut off exactly as many cells from it as there are pairs of wires to be connected, for example, in one junction box.

Using the terminal blocks is very simple:

- Unscrew one clamping screw, thereby freeing one side of the sleeve for the conductor to enter.

- Strip the insulation on the wires of the aluminum wire to a length of 5 mm.Insert it into the terminal, tighten the screw, thereby pressing the conductor to the sleeve. Tighten the screw firmly, but do not be too zealous, so as not to break the core.

- Do the same operations with the copper wire, inserting it into the sleeve from the opposite side.

Why do you have to do everything in turn? After all, you can immediately unscrew the two screws, insert the wires and tighten. This is to ensure that copper and aluminum wires do not come into contact with each other inside the brass sleeve.

As you can see, the advantages of terminal blocks are their simplicity and speed of use. This method of connection refers to detachable, if necessary, you can pull out one conductor and replace it with another.

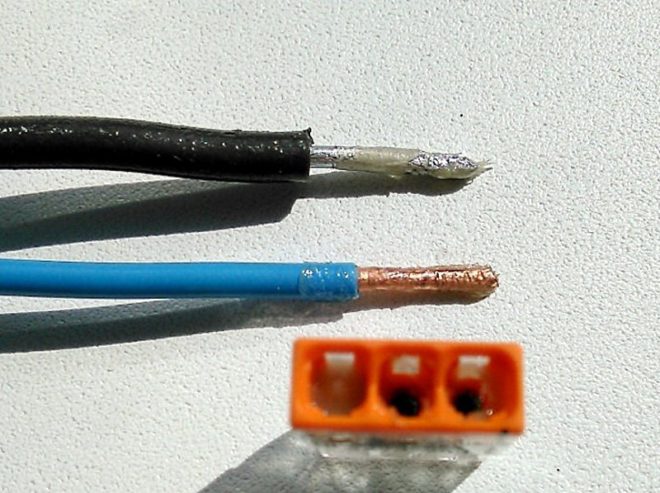

Terminal blocks are not well suited for connecting stranded conductors. In order to do this, you must first use the ferrules that will crimp the bundle of cores.

There is one more feature in the use of terminal blocks. Under the pressure of the screw at room temperature, aluminum can flow. Therefore, a periodic revision of the terminal and tightening of the contact connection, where the aluminum wire is fixed, will be required. If this is neglected, the aluminum conductor in the terminal block will loosen, the contact will weaken, begin to heat up and spark, which can result in a fire.

How to connect wires using a terminal block is shown in this video:

Self-clamping terminals

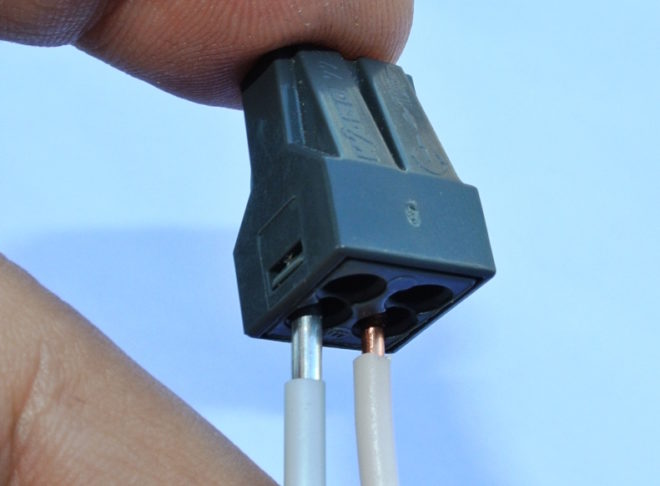

It is even faster and easier to connect aluminum and copper conductors in self-clamping terminals.

The stripped cores must be inserted into the terminal holes until they stop. There they will be automatically fixed with the help of pressure plates (it will firmly press the conductor against the tinned bar). Thanks to the transparent housing of the terminal block, it is possible to check whether the core has fully entered the terminal. The disadvantage of such devices is that they are disposable.

If you want a reusable clamp, use the lever-type clamps. The lever rises and frees the entrance to the hole into which it is necessary to insert the stripped core. After that, the lever is lowered back, thereby fixing the conductor in the terminal. This connection is detachable, if necessary, the lever rises, and the wire is removed from the terminal.

Using these terminals is also extremely simple. The terminal itself indicates how long the insulation layer of the conductor must be stripped.

The advantages and disadvantages of using WAGO terminal blocks are described in this video:

Twist connection

Twisting copper and aluminum wires is not recommended. If you cannot do without this, then first you should tin the copper conductor, that is, cover it with lead-tin solder. This will eliminate the possibility of direct interaction between aluminum and copper.

Do not forget that aluminum is very soft and brittle, it can break even under light loads, so twist it very carefully. Do not forget to properly insulate the connection, it is best in this case to use a heat-shrinkable tube.

We tried to tell you in detail whether it is possible to connect aluminum and copper wires together, as well as how to do it efficiently and reliably. Choose the most suitable method for you depending on where this connection will be switched and operated.