Properties, marking and characteristics of the SIP cable

Depending on the brand, the electrical installation CIP cable is designed to transmit electric current in networks with a voltage of 0.4 - 1, or 10 - 35 kV. The lines laid by this cable compare favorably with their predecessors in cost and do not require highly qualified personnel for installation and operation. What is a self-supporting insulated wire electric wire can be understood at first glance - there is insulation on its veins.

Content

Methods of applying and decoding marking

The abbreviation itself, used as a name, stands for Self-supporting Insulated Wire, which already determines its main characteristics. Marking on the self-supporting insulated wire can be applied alphanumeric and color marks, in compliance with the following requirements:

- If color coding is used, then it is applied in stripes at least 1 mm wide. For a self-supporting neutral wire, blue is used.

- Alphanumeric designations are embossed on insulation or applied by printing in the form of B1, B2, B3.

- Each sign shall be at least 2 mm wide and 5 mm high.

- The distance between repetitions of marking is 50 cm.

- Zero core is not marked.

This is an important point - for example, a cable can be color-coded three cores in yellow, blue and red, and the fourth is completely black. Zero in this case is the one that is completely black, and not marked with a blue stripe.

In addition to the designation of phase and neutral wires, the marking contains information about the number of current-carrying conductors and the size of their cross-section. These designations are as follows:

SIP-2 3x120 + 1x95 - 0.6 / 1 kV TU 16-705.500-2006

From the given designation it is clear that this is a cable with three phase insulated XLPE conductors with a cross section of 120 mm² and one zero without insulation, with a cross section of 95 mm². Such a Sipovsky wire is designed for voltages up to 1000 Volts and is made according to TU 16-705.500-2006.

Advantages of SIP wire

Insulated wires are superior in all respects to their predecessors, which did without a protective sheath:

- Installation speed. Instead of pulling 4 separate wires, you only need to hang one cable.

- Convenience of connection - in this regard, an electric wire without insulation requires increased attention and careful rechecking.

- Qualification of installers. During installation, it is not necessary to accurately verify the distance between the wires, in order to avoid a short circuit.

- Installation cost. There is no need to use insulators - accordingly, their purchase and installation are removed from the expense item.

- The ability to connect new points without disconnecting the entire line - for such wires, special clamps have been developed that pierce the insulation and tightly press against the current-carrying conductor.

Manufacturers claim that the cable is designed to virtually eliminate power theft. Of course, we are not talking about full protection of the lives, but making an unauthorized insert to them is really more difficult.

For more information on the characteristics and use of the cable, see this video:

Construction of SIP wires

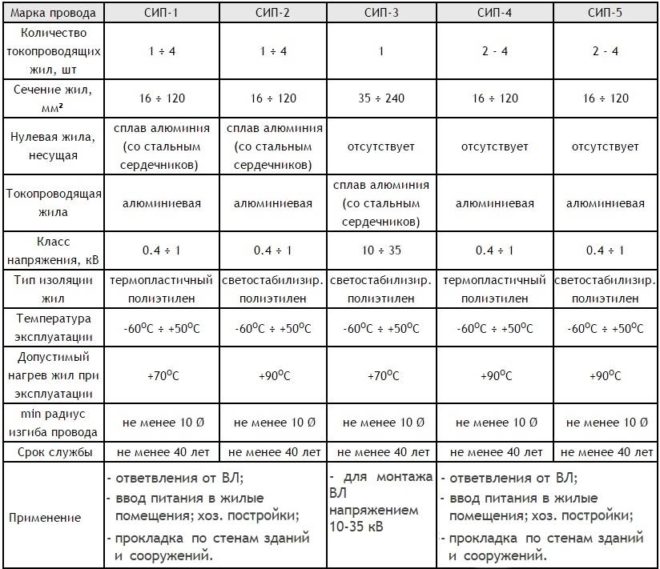

To know how to choose the right cable, you must first decide what kind of designs it is. The first symbols of the marking immediately following the abbreviation denote a type of SIP cable, which is marked as 1, 1A, 2, 2A, 4, 4n, 5 and 5n.They show what the neutral wires are made of, whether there is insulation on them, and due to which the self-supporting property of the cable is ensured (steel core inside the neutral wire or the strength of the overall structure)

SIP-1 and SIP-1A

These brands of electrical wire SIP are almost identical in their characteristics. The only difference between them is the presence of insulation on the zero core: it is not on SIP-1, but on SIP-1A there is. At the same time, the zero core itself has a steel core and can be larger, equal or smaller than the phase wires, depending on the brand and purpose of the cable. Insulation material - thermoplastic polyethylene with operating temperature from -60 to +50 C °, without prejudice to its properties withstands prolonged heating up to +70 C °. The number of cores is 2-4.

SIP-2 and SIP-2A

It has exactly the same structure and conductive characteristics as SIP-1 wires, but it was designed for operation in more severe conditions, which is expressed in the use of cross-linked light-stabilized polyethylene insulation. This is a more durable material with improved heat resistance characteristics - operating temperature from -60 to +50, but it can withstand prolonged heating up to +90 C ° and can be used in regions with cold climates. The number of cores is 2-4.

SIP-3

Unlike other brands of SIP cables, this one is made exclusively single-core, used for power lines with a voltage of 10-35 kV. It consists of a steel core, around which an aluminum alloy wire AlMgSi is wrapped. This material has high conductive and strength characteristics, and is also more resistant to corrosion. Light-stabilized polyethylene is used as insulation, which makes it possible to use the SIP cable in regions with difficult climatic conditions.

SIP-4 and SIP-4n

Wire with conductors of equal cross-section from 16 to 120 mm², the number of which can be 2-4 pieces. The load-bearing properties are equally distributed to all cores. Thermoplastic polyethylene is used as insulation. It can be operated at temperatures from -60 to +50 С °, while withstanding prolonged heating up to +90 С °. Differences in marking are due to the material from which the conductive conductors themselves are made - in SIP-4 it is pure aluminum, and SIP-4n is an aluminum alloy. The SIPn-4 marking is also used, which says that the insulation does not spread combustion.

SIP-5 and SIP-5n

By analogy with the SIP-1 and SIP-2 wires, they differ from the SIP-4 and SIP-4n cables in the insulation material, which is made of cross-linked light-stabilized polyethylene. This makes it possible to increase its resistance to prolonged heating and hypothermia by 30%, which determines the scope of use for both temperate and cold climates.

Any self-supporting insulated wire has an estimated service life of 40 years and during installation they require maintaining a bend radius of at least 10 diameters of the entire cable.

Cross-section of conductors and technical characteristics of wires

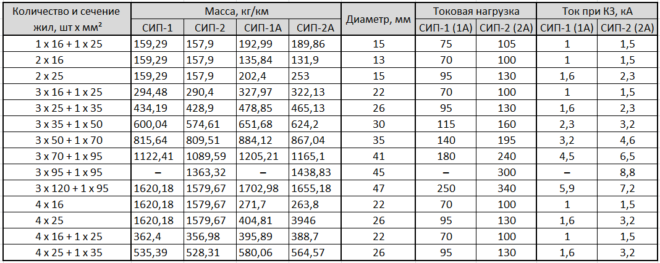

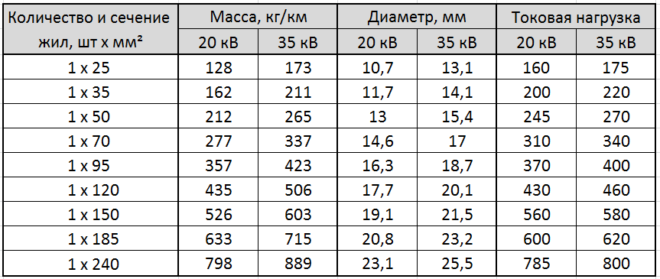

In preliminary calculations, it is imperative to take into account the cross-sectional area and weight of the wire - these data can be taken from the comparative tables.

If the connection of the SIP cable to the house is calculated, it is necessary to carefully measure the distance from the street post to the place where the wire is inserted - if it is more than 25 m, then an additional support will have to be placed under the selected cable.

Cross-sections of wires of the SIP-1 and SIP-2 brands:

Cross-section of cores and characteristics of a single-core SIP wire:

Section of conductors of wires SIP-4 and SIP-5:

For SIP wire, the main technical characteristics are as follows:

For more information about the various types of SIP cable and its installation, see this video:

Briefly about the main

SIP cables are the next generation of wires for overhead power lines, significantly increasing their efficiency. In domestic use, it is mainly used for laying lines from a transformer to a consumer and making branches from them.One of the main advantages during use is the ease of installation and operation, which allows a person to operate it without much experience in such work. But in any case, it must be remembered that all manipulations on connecting the electrical wiring to the network must be carried out by qualified electricians.