All about three-phase sockets

Unlike a household two-phase socket, a three-phase socket is connected with one strictly defined order of contacts. If in some cases it is allowed to change the location of the phase wires, then the phase and zero cannot be confused - this is a guaranteed short circuit of the wiring. As a result, three-phase sockets and plugs have a design that excludes incorrect connection.

Unlike a household two-phase socket, a three-phase socket is connected with one strictly defined order of contacts. If in some cases it is allowed to change the location of the phase wires, then the phase and zero cannot be confused - this is a guaranteed short circuit of the wiring. As a result, three-phase sockets and plugs have a design that excludes incorrect connection.

Content

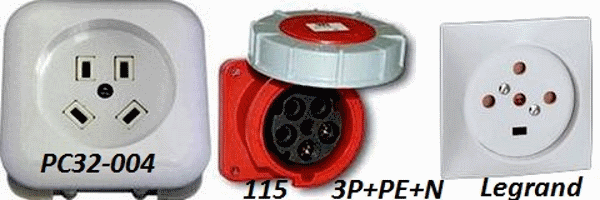

Varieties of three-phase sockets

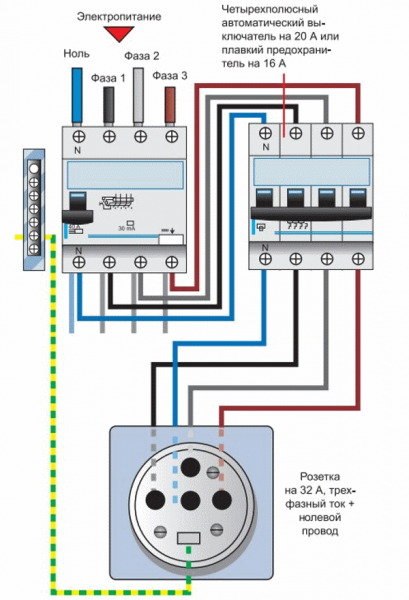

Depending on which connection diagram is used for the device, which will be powered from a three-phase outlet, four or five wires must be connected to it. In rare cases, it can be three or seven pieces - in the first case, when the control circuit and grounding are made separately, and in the second, when reinforced protection is used.

For each of these methods, its own socket is selected, with a certain number of contacts. An exception is the case if only three phases need to be connected to the device, but this happens extremely rarely. Here, a four-pin plug is taken, one of the contacts on which remains empty. You should not buy three-pin sockets that are in stores - in fact, they are household ones, designed for 220 volts - phase, zero and ground. They look like three-phase ones, since they can be connected to loads with a current strength of up to 32 Amperes.

The dimensions of three-phase outlets are usually quite significant, so these devices are not intended for mounting inside the wall, but are screwed from the outside onto dowels or a stand made for them.

Four-pin sockets

They are most common in everyday life and at work, in networks where the neutral wire also serves as a ground wire and is connected to the device case. The socket is a base that is fixed on a wall or stand and then a protective cover is put on it.

They are most common in everyday life and at work, in networks where the neutral wire also serves as a ground wire and is connected to the device case. The socket is a base that is fixed on a wall or stand and then a protective cover is put on it.

The design of the sockets and the location of the terminals may differ, so if you plan to connect several devices to one outlet, then it would be useful to ask the store which of them are constantly on sale.

When connecting, you need to be careful with zero - in appearance this contact looks like all the others, but it is marked with a corresponding icon on the base of the socket or its cover.

The wires are connected to the contacts with a bolt connection. Since most often the contacts themselves are made of brass, it is permissible to use aluminum wires. If desired, you can use metal washers for reinsurance.

Five-pin sockets

They are used in modern electrical circuits, where the protective, grounding zero is connected separately from the worker, for which a separate contact is needed on the outlet.

They are used in modern electrical circuits, where the protective, grounding zero is connected separately from the worker, for which a separate contact is needed on the outlet.

Although only one wire is added compared to four-pin sockets, five-pin sockets are significantly larger in size. Considering that rather rigid cables are often connected to them, they must be well fixed to the wall.

The design of the box, the location of the terminals and their shape may differ, so it is better to select standard models so that, on occasion, you can freely find a replacement.

When buying, it is advisable to pay attention to the method of connecting the wires - if it is a bolt, with the tip of which the core is pressed against the contact, then over time it can break at the attachment point. The solution to the problem may be the choice of a socket model with other fastening methods or the use of lugs for wires that crimp the conductors.In general, if you need to use bolt clamps, then nothing terrible will happen - you just need to check the contacts more often.

How phase wires are connected

If an electric heater or similar device that does not have an electric motor is connected to the outlet, then the order of connecting the phase wires does not matter - the device will work in any case. When the connection diagram is intended for an electric motor, then it is imperative to check whether it turns in the right direction. If the rotation occurs in the opposite direction from the required direction, then any two phase wires must be interchanged - in the socket itself, on the plug or at the motor terminals.

Ideally, electricians should check the phase order so that the same motor is spinning in the same direction everywhere. In practice, a device such as an electric motor is installed permanently and it is much easier to swap the contacts than to follow the connection diagrams. This is especially true for enterprises that have been operating for many years, and in which these same schemes have already been repeatedly changed and reconnected for different needs.

Three-phase sockets and grounding

The choice and connection of a three-phase outlet is largely determined by the method of connecting the motor windings, heating elements of a boiler or other device. If a delta connection is used, then the windings or heating elements are simply connected in series with each other - the end of one to the beginning of the next, and so on in a circle. Phase wires are connected to the places of twists (there will be three in total), and zero is essentially not needed here - it is used only for the control circuit, which can be quite far from the motor itself.

In this case, the neutral wire can be "put" on the device case if it is also a ground. If the bed is grounded separately, then zero does not connect anywhere at all, except for those cases when zeroing is required. A four-pin socket is sufficient here.

Star connection - one of the ends of each winding is connected to the neutral wire, and the rest - each to its own phase wire. In this case, it is much more practical to use a five-pin outlet, through which phases, zero and ground are separately supplied.

Star connection with additional protection - used if additional circuit protection is used, when each phase is connected through a separate RCD. In this case, three phases, three zeros and ground must be connected to the device, for which you will have to find a seven-pin socket and plug.

What to look for when buying

If it is necessary to choose a three-phase outlet, attention should be paid to the following points:

- The current strength for which it is designed. Most often, you have to choose between models with 16, 32 or 64 amperes, depending on the device to which they will be connected.

- The level of protection against moisture and dust. To check, you need to look for the "IP" marking in the characteristics - the higher the number, the more reliable the protection. In practice, pay attention to this only if the socket is installed in a place with very high humidity.

- You need a stationary outlet or a mobile one. To put it simply, they will hook it to the wall or make it carry.

- The number of contacts is selected depending on the use of a specific connection scheme.

- If sockets are purchased with self-tightening screwless contacts, then you need to make sure that they are working properly so that they are not disposable.

Design tricks, shape and mutual arrangement of contacts - all these details depend on a specific manufacturer and may differ insignificantly in different device models. They only affect the convenience of finding a new outlet if you need to replace it.